Brake Pads | Which Is Right For Me?

Choosing the correct brake pad compound is the key to optimal stopping performance and longevity.

It is widely understood that heat is the biggest contributor to premature brake wear. Friction, outside of the pad's designed operating temperature (too cold), is also a common issue we see amongst weekend track cars, who use an aggressive sprint pad during off track activities such as the daily commute. Below is a guide to which compound we recommend for most common applications. Please contact us to discuss any specific motorsport requirements.

General - Heavy Street Use:

Our entry level pad offering kept in stock to suit most common performance makes and models.

This compound is what we recommend for all cars that are driven spiritedly on a regular basis.

Material: Non asbestos organic

Temperature: 0-600c

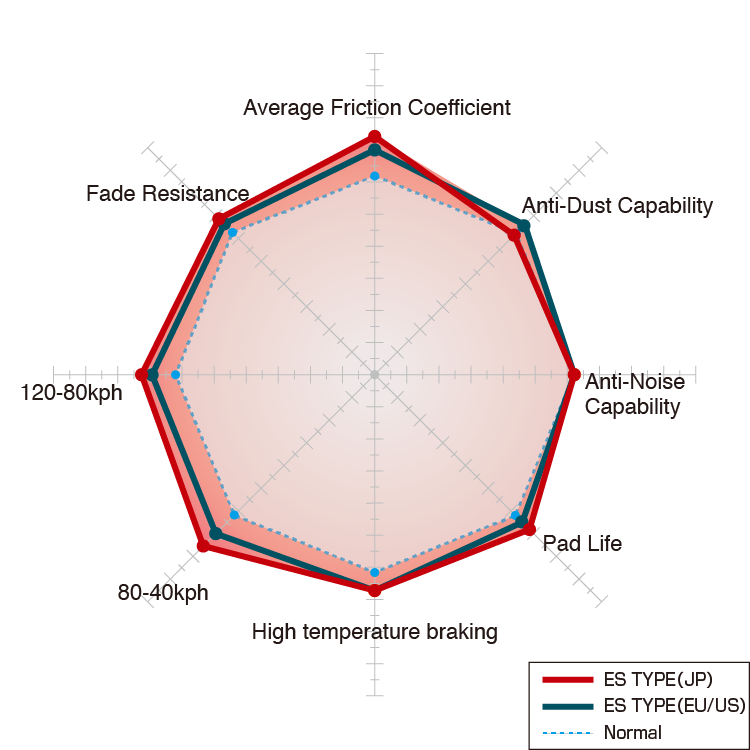

The radar chart below compares the DIXCEL ES Type pads and standard OEM pads, based on actual characteristic test results.

Premium pad compound available for most high performance or luxury vehicles seeking a low dust solution without sacrificing brake performance.

We recommend these pads for BMW M, Mercedes AMG or Audi RS vehicles that don't participate in race activities.

Material: Ceramic & non asbestos organic

Temperature: 0-500c

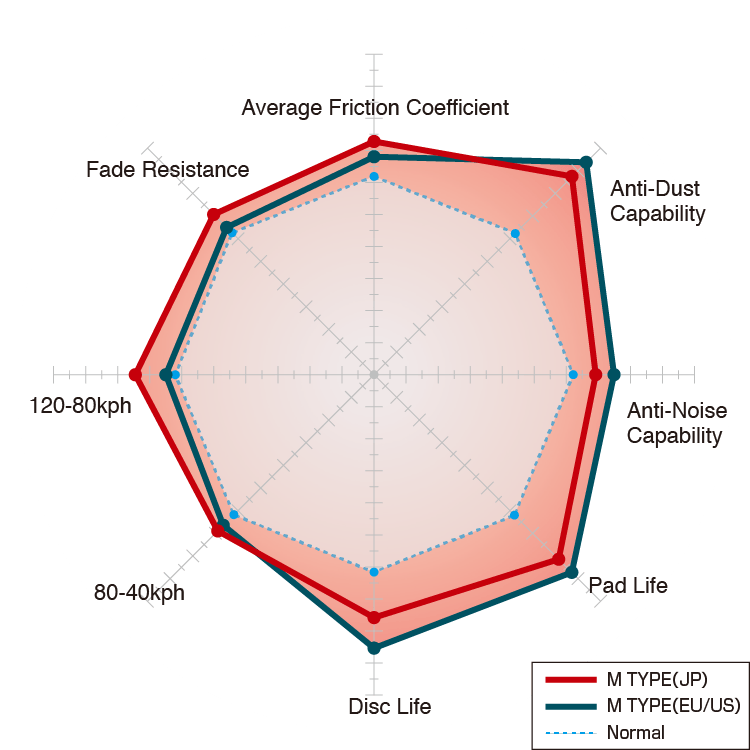

The radar chart below compares the DIXCEL M Type pads and standard OEM pads, based on actual characteristic test results.

Our mid-range performance pad designed with characteristics and temperature range put together for aggressively driven, high powered JDM vehicles.

Material: Non asbestos, low steel

Temperature: 0-700c

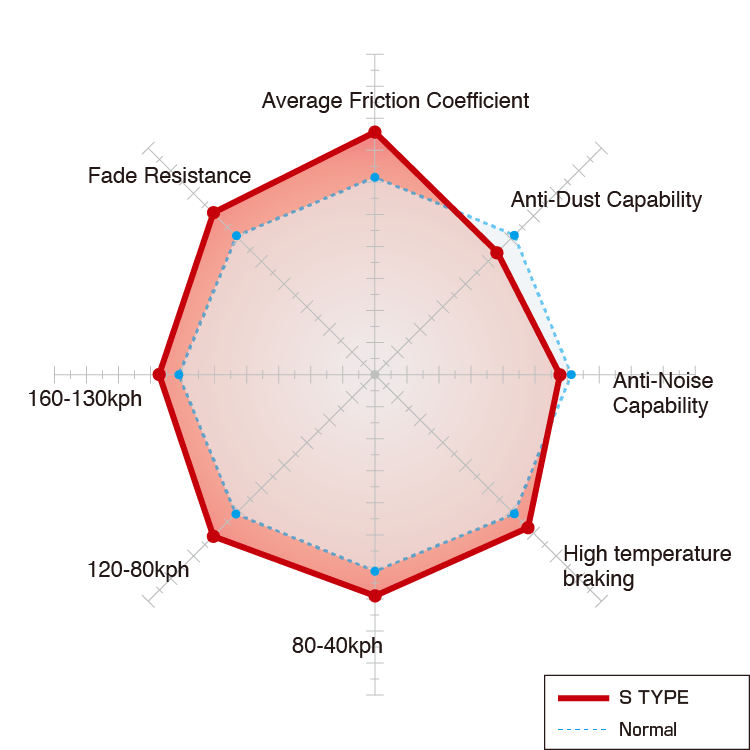

The radar chart below compares the DIXCEL S Type pads and standard OEM pads, based on actual characteristic test results.

Hybrid Street & Circuit Use:

Our top of the range street pad boasts circuit-use levels of thermal capacity and fade resistance.

We recommend this pad to anybody who use their vehicle both on the street and club level circuit racing.

Material: Graphite metallic

Temperature: 0-850c

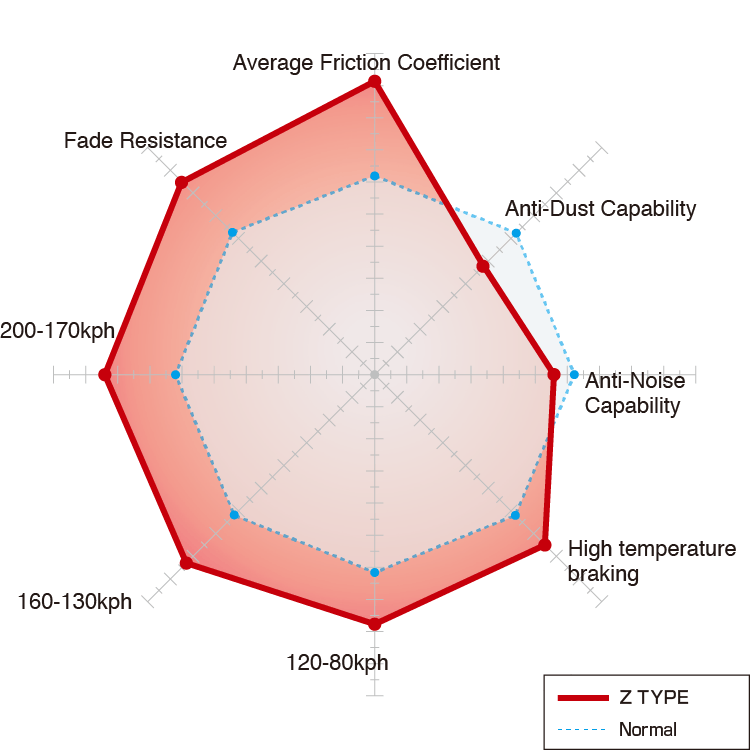

The radar chart below compares the DIXCEL Z Type pads and standard OEM pads, based on actual characteristic test results.

Circuit Use:

Our race pad offering was originally developed during Japanese endurace races to achieve excellent pad and disc life, stable pressure and modulation over extended race durations and now it has been tested and proven in Australian motorsport.

This pad is recommended for high powered vehicles with little to no aftermarket brake cooling upgrades.

Material: Carbon semi-metallic

Temperature: 200-900c